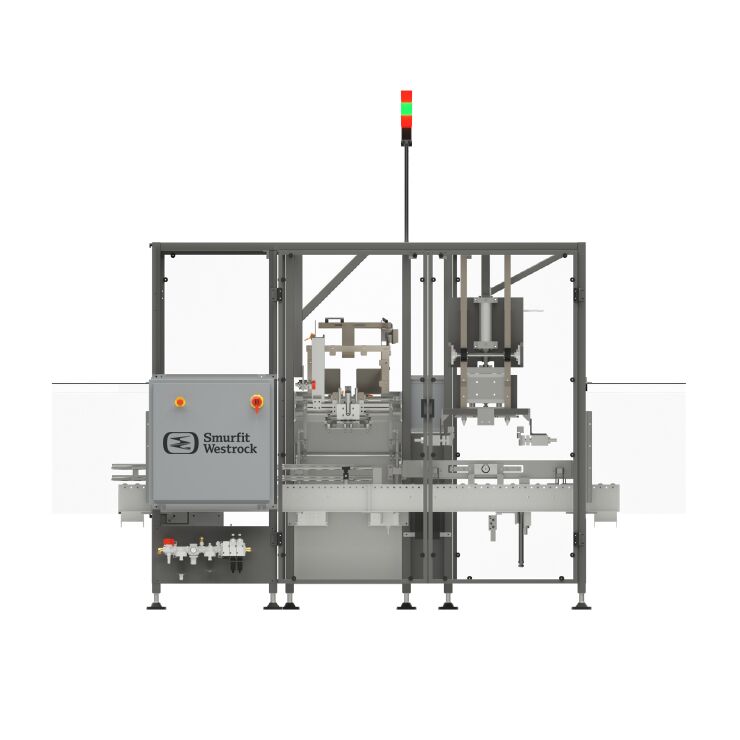

Clip & Collar Machines

Request a quote

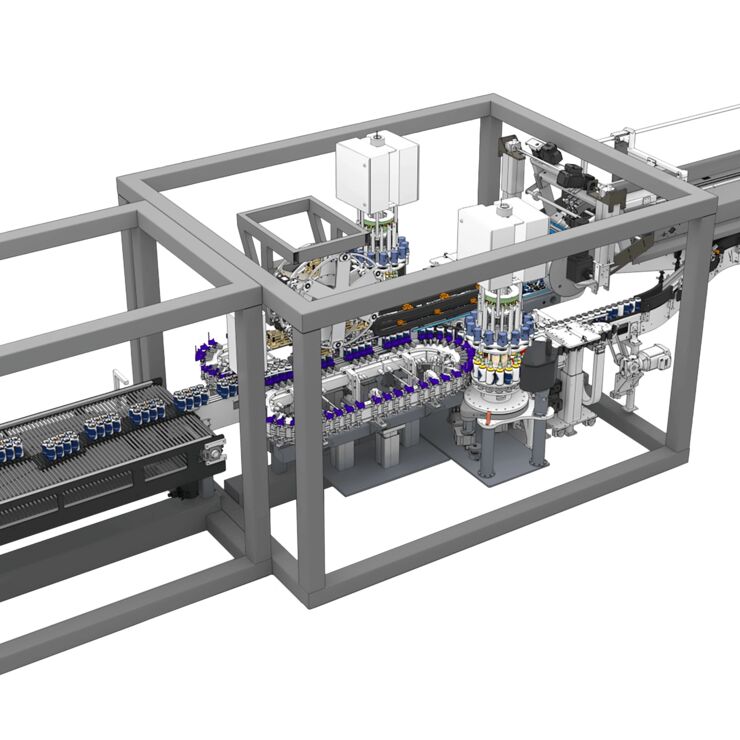

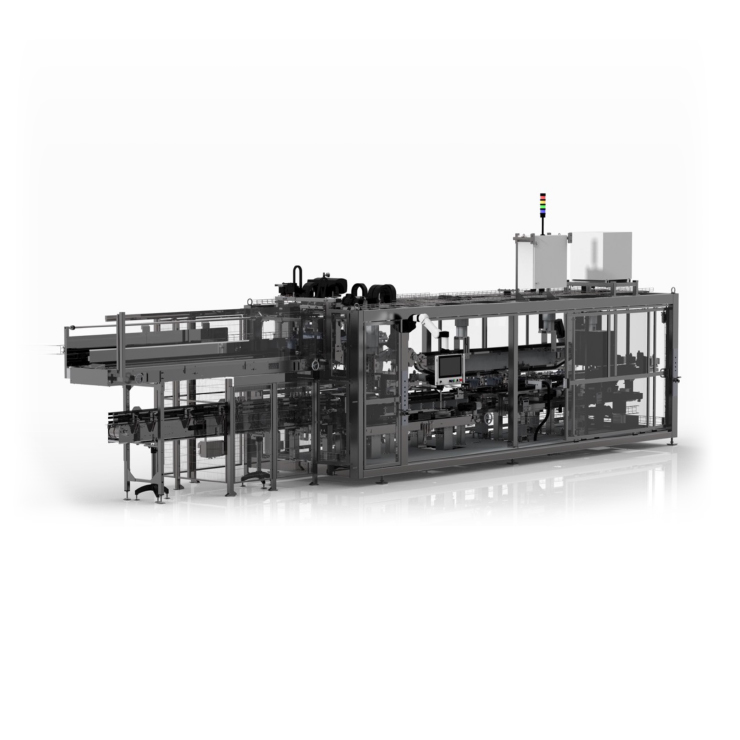

Our ringing machines help brands replace single-use plastic rings and shrink wrap with a durable, paper-based alternative. With options for both cans and bottles, our ringing machine automation applies printable, protective rings that stand out on the shelf and reduce plastic usage. With our ringing machine portfolio, you can expect:

Versatility

Our ringing machine portfolio includes options for manual to high-speed automation and supports a wide range of can and bottle sizes and formats, allowing you to find the right system to meet your needs.

Space Efficiency

With compact options, you can find a ringing machine to fit within your footprint.

Sustainability

By offering a paper-based alternative to plastic rings and shrink wrap, our ringing machines deliver on brands’ sustainability goals through the use of paper fiber, a renewable raw material.

Visual Impact

The paper-based rings applied by our ringing machine automation have a fully printable surface for customized branding and graphics that elevate the consumer experience and deliver powerful shelf impact.

Operational Efficiencies

Our ringing machines can help you streamline your operations and enable essential labor reallocation.

Explore Our Ringing Machine Portfolio for Cans & Bottles

Real Results: How Our Customers Succeed With This Product

Get in touch

* Mandatory Field